How to set the timing on a Accucraft Ruby, explained

The Accucraft Ruby is a popular live steam locomotive model produced by Accucraft, a well-known manufacturer of model trains. Specifically designed for hobbyists and model railroad enthusiasts, the Ruby is a small, narrow-gauge locomotive that operates using real steam power, offering an authentic miniature train experience. It’s often favored by those who are interested in the mechanics of steam engines but prefer a simpler and more accessible locomotive to operate and maintain compared to larger or more complex models. For a detailed explanation of how to set the timing on a Accucraft Ruby, see below.

The Ruby is designed in 1:20.3 scale and is based on generic narrow-gauge steam locomotives, making it highly customizable. Many hobbyists enjoy modifying the Ruby to resemble specific historical engines or creating unique, personalized versions. The locomotive runs on 45mm gauge track, which is the standard for G-scale trains, and can be operated manually or radio-controlled, depending on how it’s outfitted.

It is fueled by butane and features a single-cylinder oscillating steam engine. Its simple design makes it an entry-level live steam locomotive, but it’s also appreciated by seasoned enthusiasts for its reliability and ease of use.

Common problems with the Accucraft Ruby

Some common issues that arise with the Accucraft Ruby live steam locomotive involve steaming difficulties, mechanical adjustments, and operational consistency.

One frequent issue is related to the boiler, where it may take longer than expected to build pressure or struggle to maintain a steady flame. For example, users report that the butane burner sometimes produces a weak or irregular flame, which can result in longer heat-up times and less steam pressure to power the locomotive efficiently

Additionally, fine-tuning the steam pressure and ensuring proper water levels are crucial to avoid underperformance.

Mechanical problems are also reported, such as difficulties with the reversing valve, which controls the locomotive’s direction. Poor setup or misalignment of this valve can cause the engine to lose power or behave unpredictably. Adjustments to this mechanism often require precision to ensure smooth operation(

Furthermore, some users experience issues with assembly, especially if they’ve built the Ruby from a kit. Misalignments during assembly or missing components can prevent the engine from running properly. Hobbyists frequently need to fine-tune various mechanical parts, such as the cylinder or steam pipes, to optimize the performance of the locomotive(

Despite these issues, the Ruby is favored for its simplicity and adaptability, and many enthusiasts enjoy customizing or modifying their models to resolve these problems.

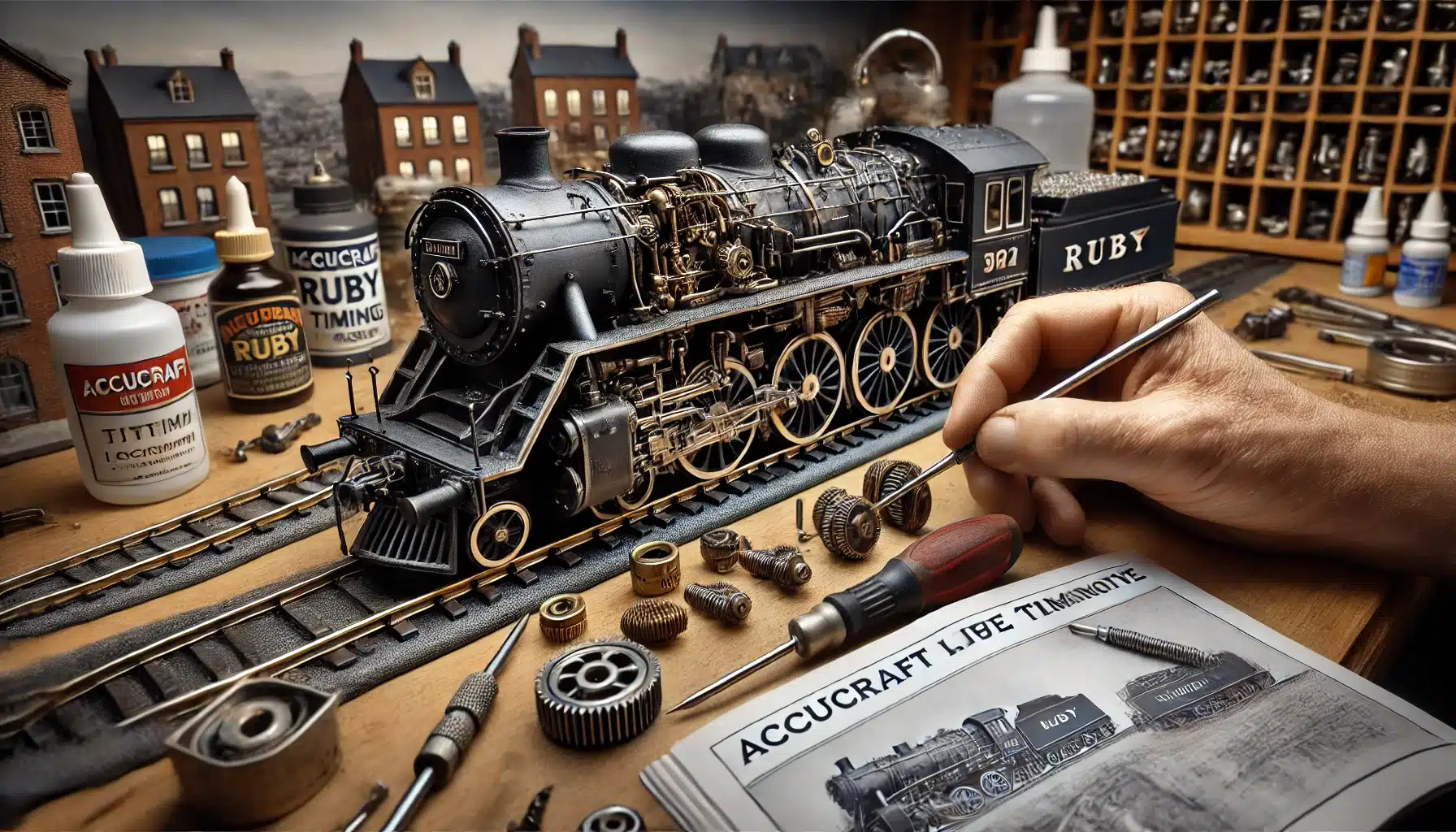

How to set the timing on a Accucraft Ruby

To set the timing on an Accucraft Ruby, the process involves adjusting the valve gear to ensure that the steam distribution to the pistons is correctly synchronized. This ensures efficient operation of the locomotive. Here’s an overview of the procedure:

- Preparation: Before adjusting the timing, gather small screwdrivers and lubricant, and make sure the locomotive is clean and free of debris. You’ll also need to reference the Ruby manual for specific details.

- Access the Timing Mechanism: Remove the boiler to expose the valve gear assembly. The timing gear is usually located near the pistons.

- Checking and Adjusting the Timing: Start by checking the current timing alignment using the valve rod and markings. Turn the wheels to position the piston valve at its maximum extension. If the timing is off, use a small screwdriver to adjust the valve gear by turning the locknuts. Adjust gradually and check frequently to ensure the steam chest is correctly aligned when the wheels are in motion.

- Reassemble and Test: After adjustments, reassemble the locomotive and lubricate the moving parts. Perform a test run to check for smooth operation and listen for any unusual noises.

- Fine-tuning: If the locomotive runs poorly in reverse, it may be necessary to adjust the valve’s position slightly to balance forward and reverse performance.

Using thread lock on screws and locknuts can help maintain settings once the timing is adjusted. Regular maintenance and fine-tuning ensure consistent performance.

ChatGPT

Writer

ChatGPT is a large language model developed by OpenAI, based on the GPT-3.5 architecture. It was trained on a massive amount of text data, allowing it to generate human-like responses to a wide variety of prompts and questions. ChatGPT can understand and respond to natural language, making it a valuable tool for tasks such as language translation, content creation, and customer service. While ChatGPT is not a sentient being and does not possess consciousness, its sophisticated algorithms allow it to generate text that is often indistinguishable from that of a human.