Allied Critical Metals Expands High Grade Footprint at Borralha Tungsten Project

New Step-Out and Infill Results Build Confidence in Resource Growth and Model Robustness

Vancouver, British Columbia–(Newsfile Corp. – September 29, 2025) – Allied Critical Metals Inc. (CSE: ACM) (OTCQB: ACMIF) (FSE: 0VJ0) (“Allied” or the “Company”), which is focused on its 100% owned past producing Borralha and Vila Verde tungsten projects in northern Portugal, is pleased to report assay results from two additional Reverse Circulation (RC) drill holes – Bo_RC_21 and Bo_RC_26 – from its ongoing 5,000-metre campaign at the 100%-owned Borralha Tungsten Project in northern Portugal.

These latest results continue to demonstrate the scale and continuity of mineralization at the Santa Helena Breccia (SHB), with intercepts that support both lateral expansion and model refinement.

Highlights:

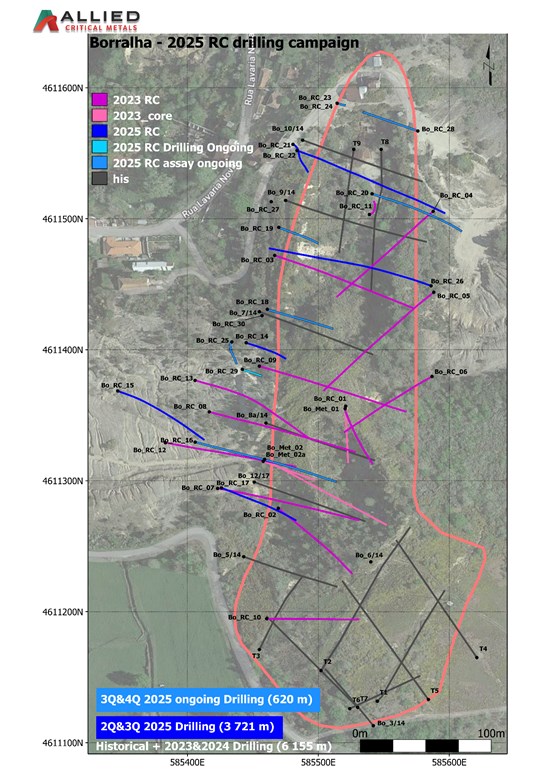

Bo_RC_21: This drill hole is a west step-out at the North edge of the St. Helena Breccia that confirms continuity of the recently discovered north-dipping lode outside the current MRE envelope, upgrading this area to a large coherent mineralized “in section” corridor with more than 100 m width.

- 42.0m at 0.19% WO3 (from 256.0 m to 298.0 m), including:

- 24.0m at 0.28% WO3 (from 256.0 m to 280.0 m)

- 18.0m at 0.34% WO3 (from 256.0 m to 274.0 m)

- 8.0m at 0.40% WO3 (from 266.0 m to 274.0 m)

- 4.0m at 0.62% WO3 (from 266.0 m to 270.0 m)

Bo_RC_26: This drill hole is an infill hole targeting the north-central zone, enhancing confidence in the resource model and suggesting western expansion potential.

- 26.0m at 0.24% WO3 (from 140.0 m to 166.0 m), including:

- 12.0m at 0.38% WO3 (from 140.0 m to 152.0 m)

- 2.0m at 2.02% WO3 (from 140.0 m to 142.0 m)

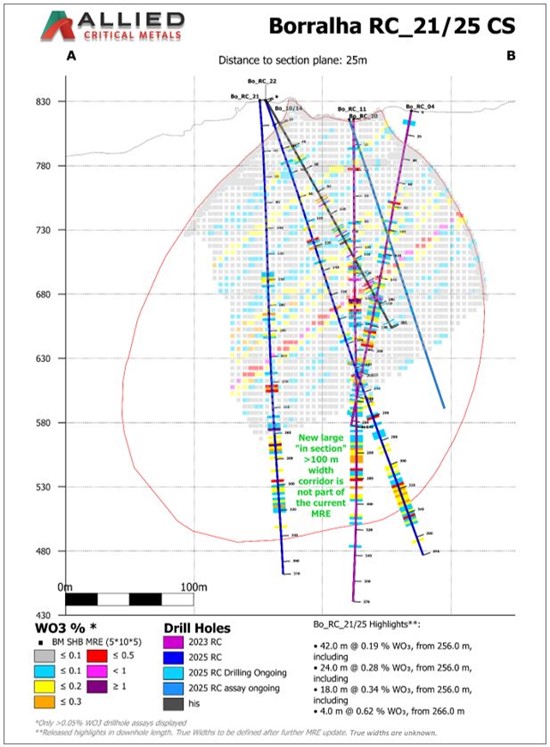

Drill Program Progress

To date, 3,721 metres of RC drilling have been completed out of the planned 5,728 metres, with multiple assay results already confirming thick mineralized zones and consistent grade distribution. The current campaign is designed to support:

- The expansion of the Mineral Resource Estimate (MRE), expected in Q4 2025.

- The development of a robust Preliminary Economic Assessment (PEA).

- The delineation of potential higher-grade corridors for future mine planning.

Roy Bonnell, CEO and Director of ACM, commented: “With each new intercept, we are seeing our understanding of Borralha evolve and strengthen. Bo_RC_21 confirms mineralization well beyond the current model, while Bo_RC_26 tightens the block model in a key zone. Together, these results support both immediate growth and long-term confidence in Borralha’s development potential.”

Table 1 – Drill Hole Collar Locations

| ID | Coordinates (WGS84) | Az.(º) | Dip .(º) | PFD (m) | DEPTH (m) | Status | |

| Bo_RC_14/25 | 585445 | 4611405 | 109 | 80 | 250 | 264.00 | Press Released |

| Bo_RC_15/25 | 585347 | 4611368 | 109 | 70 | 300 | 255.00 | Press Released |

| Bo_RC_16/25 | 585406 | 4611329 | 105 | 60 | 240 | 251.00 | Assay ongoing |

| Bo_RC_17/25 | 585426 | 4611294 | 109 | 75 | 250 | 255.00 | Press Released |

| Bo_RC_18/25 | 585461 | 4611431 | 109 | 75 | 300 | 241.00 | Assay ongoing |

| Bo_RC_19/25 | 585470 | 4611493 | 109 | 82 | 350 | 248.00 | Assay ongoing |

| Bo_RC_20/25 | 585541 | 4611519 | 109 | 70 | 350 | 237.00 | Assay ongoing |

| Bo_RC_21/25 | 585481 | 4611557 | 109 | 85 | 400 | 370.00 | Current Press Release |

| Bo_RC_22/25 | 585484 | 4611552 | 109 | 70 | 360 | 375.00 | Press Released |

| Bo_RC_23/25 | 585514 | 4611588 | 109 | 80 | – | 45.00 | Cancelled |

| Bo_RC_24/25 | 585514 | 4611588 | 0 | 90 | – | 42.00 | Cancelled |

| Bo_RC_25/25 | 585434 | 4611406 | 0 | 90 | 300 | 291.00 | Assay ongoing |

| Bo_RC_26/25 | 585586 | 4611449 | 289 | 60 | 400 | 278.00 | Current Press Release |

| Bo_RC_27/25 | 585464 | 4611513 | 0 | 90 | 350 | 251.00 | Assay ongoing |

| Bo_RC_28/25 | 585576 | 4611567 | 290 | 80 | 400 | 318.00 | Assay ongoing |

| Bo_RC_29/25 | 585449 | 4611386 | 109 | 87 | 300 | – | Drilling ongoing |

| Bo_RC_30/25 | 585443 | 4611429 | 0 | 90 | 320 | – | Drilling ongoing |

Table 2 – Current Campaign Interval Highlights Update

| New ID | From (m) | To (m) | DH length (m) [1] | True Width Factor [1] | True Width (m) [1] | WO3 (%) |

| Bo_RC_14/25 | 52.0 | 64.0 | 12.0 | tbd [2] | – | 4.27 |

| inc. | 52.0 | 58.0 | 6.0 | “ | – | 8.39 |

| Bo_RC_15/25 | 164.0 | 166.0 | 2.0 | 0.88 | 1.8 | 0.97 |

| Bo_RC_17/25 | 52.0 | 152.0 | 100.0 | 0.90 | 89.9 | 0.21 |

| inc. | 92.0 | 124.0 | 32.0 | 0.90 | 28.8 | 0.33 |

| inc. | 106.0 | 120.0 | 14.0 | 0.90 | 12.6 | 0.52 |

| inc. | 110.0 | 116.0 | 6.0 | 0.90 | 5.4 | 0.74 |

| Bo_RC_21/25 | 256.0 | 298.0 | 42.0 | tbd [2] | unknown | 0.19 |

| inc. | 256.0 | 280.0 | 24.0 | “ | unknown | 0.28 |

| inc. | 256.0 | 274.0 | 18.0 | “ | unknown | 0.34 |

| inc. | 266.0 | 274.0 | 8.0 | “ | unknown | 0.40 |

| inc. | 266.0 | 270.0 | 4.0 | “ | unknown | 0.62 |

| Bo_RC_22/25 | 284.0 | 348.0 | 64.0 | tbd [2] | unknown | 0.12 |

| inc. | 316.0 | 332.0 | 16.0 | “ | unknown | 0.21 |

| Bo_RC_26/25 | 140.0 | 166.0 | 26.0 | 0.39 | 10.2 | 0.24 |

| inc. | 140.0 | 152.0 | 12.0 | 0.40 | 4.7 | 0.38 |

| inc. | 140.0 | 142.0 | 2.0 | 0.40 | 0.8 | 2.02 |

Notes: [1] Reported intervals are downhole lengths. Estimated true widths were calculated from hole orientation and the interpreted geometry of the mineralized corridors. Estimates may vary locally where geometry changes. Where intervals fall outside the resource block-model domains, true widths are not estimated and only downhole lengths are reported. [2] True widths are unknown, to be defined after further MRE update.

Figure 1 – Drill collar plan showing planned holes for the ongoing 5,728 m RC campaign at the Borralha Project. The red outline delineates the main mineralized breccia zone

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/11632/268354_73bff5a8941de85b_001full.jpg

Figure 2 – Geological Cross-Section for hole Bo_RC_21/25.

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/11632/268354_alliedcritical2.jpg

Strategic Context

These results follow recently reported ultra-high-grade and extensive tungsten intercepts, including 12.0 m @ 4.27% WO₃ (Bo_RC_14/25), and 100.0 m @ 0.21% WO₃ (Bo_RC_17/25), confirming a significant system within the Santa Helena Breccia. Allied is working systematically to define both bulk-mineable zones and higher-grade corridors that can support future underground or hybrid extraction scenarios.

Next Steps

Drilling is ongoing, with further results expected in the coming weeks. Step-out holes are targeting both western and northern extensions of SHB, while infill drilling is refining the core resource model. Results will continue to inform the MRE and subsequent economic studies.

In light of the recent new discovery of the very high grade corridor at the west dip of the central area of the Breccia, the Company has adapted the current campaign towards confirming, and potentially expanding upon the recent very high grade intercepts.

Sampling, QA/QC and Analytical Notes

Drilling was completed using reverse-circulation (RC). All sample bags were pre-labelled with a unique internal sequence number used consistently for the assay sample and corresponding reject. Sampling was conducted on 2.0 m intervals for analytics. For each 2.0 m interval, two 1.0 m reject samples were also collected as representative splits. Splitting was performed at the rig via a rotary splitter integral to the RC cyclone.

Sampling followed pre-prepared sample lists that recorded downhole metreage, sequence, and the placement of Certified Reference Materials (CRMs) and field duplicates. CRMs were inserted at a rate of 1 in 20 samples (5%) and field duplicates at 1 in 20 samples (5%), arranged so that every 10th sample alternated between a CRM and a duplicate.

Analytical and reject samples were boxed at the drill site and transported by company personnel to the project core/logging facility. Analytical samples were stored on labelled pallets pending direct shipment to ALS’s preparation laboratory in Seville, Spain. Pulps and rejects were subsequently stored securely in the project logging room.

At ALS Seville, samples were crushed to 70% passing 2 mm, riffle-split to ~250 g, and pulverized using hardened steel to 85% passing 75 μm. Pulps were shipped to ALS Loughrea (Ireland) for analysis. The primary analytical method was ME-MS81 (lithium borate fusion with ICP-MS finish). Base metals were also reported using ME-4ACD81 (four-acid digestion with ICP-MS finish). Over-limit tungsten results were re-assayed using W-XRF15b (lithium borate fusion with XRF). Analytical results were delivered directly by ALS to the Company via secure electronic transfer.

Primary disclosure remains the reported grade and interval length (and true width where known).

To the best of the Company’s knowledge, no drilling, sampling, recovery, or other factors have been identified that would materially affect the accuracy or reliability of the data referenced herein.

Qualified Person

The scientific and technical information in this news release has been reviewed and approved by Mr. Vítor Arezes, BSc, MIMMM (QMR) (Membership Nº. 703197, Vice-President Exploration of Allied Critical Metals, who is a Qualified Person for the purposes of National Instrument 43-101 – Standards of Disclosure for Mineral Projects. Mr. Arezes is not independent of Allied Critical Metals Inc. as he is an officer of the Company.

About the Borralha Tungsten Project

Allied’s Borralha Tungsten Project is one of the largest and most historically significant past-producing tungsten operations in Western Europe. Located in northern Portugal, Borralha was once the second-largest tungsten mine in the country and supplied strategic materials to European and Allied industries during the 20th century, including both World Wars and the Cold War period.

Today, the project is undergoing a modern revitalization based on a combination of scale, grade, metallurgy, and jurisdictional strength. Mineralization is dominated by coarse-grained wolframite, which is highly desirable in global markets due to its favorable processing characteristics and higher recoveries compared to scheelite-bearing deposits.

Borralha benefits from existing infrastructure, shallow mineralization, and a simple processing route, making it one of the most advanced tungsten development projects in the European Union. These attributes are particularly important in the context of the EU Critical Raw Materials Act (2024/1252) and NATO strategic autonomy initiatives, both of which explicitly identify tungsten as a defense-critical raw material subject to severe supply risk.

With the EU currently dependent on over 80% of its tungsten imports from China, Borralha represents a rare and strategic opportunity to develop a secure, domestic, and NATO-aligned supply source. As Allied continues to advance drilling, resource expansion, and economic studies, Borralha is poised to play a central role in reshaping Europe’s tungsten landscape-supporting both decarbonization technologies and defense-industrial resilience.

Understanding Tungsten

To understand tungsten, it is critical to understand the difference between wolframite tungsten mineralization and scheelite tungsten mineralization. Scheelite often reports higher grades but is typically more costly and complex to process, requiring flotation methods with higher capital and operating expenditures and lower recoveries.i In contrast, wolframite can be processed more efficiently using gravity and magnetic separation, resulting in lower costs and higher recoveries, making lower grades economically viable in wolframite deposits. For example, a lower grade wolframite deposit can be more attractive than a slightly higher grade scheelite deposit.ii

It is also important to recognize that China, Russia, and North Korea control approximately 87% of the world’s tungsten supply, using cheap labor and minimal environmental standards in authoritarian regimes.iii As a result, production costs and grades in these countries are not comparable to Western projects, which operate under higher labor, ESG, and energy cost structures. Evaluating projects outside these regions provides a realistic benchmark for what grades and intercepts are economically viable while supporting secure, NATO-aligned supply chains.

For Allied, this context is significant. Allied’s operations in secure jurisdictions align with Western critical mineral needs, avoiding geopolitical risks associated with China and Russia while positioning the Company to benefit from growing tungsten demand across defense, aerospace, and electrification sectors. Allied’s wolframite tungsten mineralization and secure location position it as a strategic and responsible tungsten exploration company, well placed to take advantage of a rising-demand market. iv

About Allied Critical Metals Inc.

Allied Critical Metals Inc. (CSE: ACM) (OTCQB: ACMIF) (FSE:0VJ0) is a Canadian-based mining company focused on the expansion and revitalization of its 100% owned past producing Borralha Tungsten Project and the Vila Verde Tungsten Project in northern Portugal with advantageous wolframite tungsten mineralization. Tungsten has been designated a critical metal by the United States and other western countries, as they are aggressively seeking friendly sources of this unique metal. Currently, China, Russia and North Korea represent approximately 86% of the total global supply and reserves. Tungsten is used in a variety of industries such as defense, automotive, manufacturing, electronics, and energy.

ON BEHALF OF THE BOARD OF DIRECTORS

“Roy Bonnell”

Roy Bonnell

CEO and Director

For further information or investor relations inquiries, please contact:

Dave Burwell

Vice President, Corporate Development

Email: daveb@alliedcritical.com

Tel: 403-410-7907

Toll Free: 1-888-221-0915

Please visit our website at www.alliedcritical.com.

Also visit us at:

LinkedIn: https://www.linkedin.com/company/allied-critical-metals-inc

X: https://x.com/@alliedcritical/

Instagram: https://www.instagram.com/alliedcriticalmetals/

The Canadian Stock Exchange does not accept responsibility for the adequacy or accuracy of this release.

Cautionary Statement Regarding Forward-Looking Information

This news release contains “forward-looking statements”, including with respect to the use of proceeds. Wherever possible, words such as “may”, “would”, “could”, “should”, “will”, “anticipate”, “believe”, “plan”, “expect”, “intend”, “estimate”, “potential for” and similar expressions have been used to identify these forward-looking statements. These forward-looking statements reflect the current expectations of the Company’s management for future growth, results of operations, performance and business prospects and opportunities and involve significant known and unknown risks, uncertainties and assumptions, including, without limitation, those listed in the Company’s Listing Statement and other filings made by the Company with the Canadian securities regulatory authorities (which may be viewed under the Company’s profile at www.sedarplus.ca ). Examples of forward-looking statements in this news release include, but are not limited to, statements regarding the proposed timeline and use of proceeds for exploration and development of the Company’s mineral projects as described in the Company’s Listing Statement, news releases, and corporate presentations. Should one or more of these risks or uncertainties materialize or should assumptions underlying the forward-looking statements prove incorrect, actual results, performance or achievements may vary materially from those expressed or implied by the forward-looking statements contained in this news release. These factors should be considered carefully, and prospective investors should not place undue reliance on the forward-looking statements. This list is not exhaustive of the factors that may affect any of the Company’s forward-looking statements and reference should also be made to the Company’s Listing Statement dated April 23, 2025 and news release dated May 16, 2025, and the documents incorporated by reference therein, filed under its SEDAR+ profile at www.sedarplus.ca for a description of additional risk factors. The Company disclaims any intention or obligation to revise forward-looking statements whether as a result of new information, future developments or otherwise, except as required by law.

iInternational Tungsten Industry Association (ITIA). (2023). Tungsten: Global industry, markets & outlook. Retrieved from https://www.itia.info

ii International Tungsten Industry Association (ITIA). (2023). Tungsten: Global industry, markets & outlook. Retrieved from https://www.itia.info

iii International Tungsten Industry Association (ITIA). (2023). Tungsten: Global industry, markets & outlook. Retrieved from https://www.itia.info

iv International Tungsten Industry Association (ITIA). (2023). Tungsten: Global industry, markets & outlook. Retrieved from https://www.itia.info

To view the source version of this press release, please visit https://www.newsfilecorp.com/release/268354