3D printed organs, a pipe dream? Not any more.

3D printed organs, a pipe dream? Not any more.

In what is being hailed as a breakthrough in regenerative medicine, researchers at the University of Bristol and Oxford University have created a 3D-printer which can make living tissues by printing together stem cells into a complex structure.

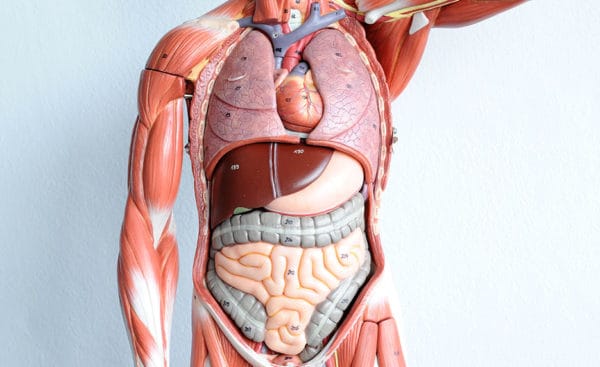

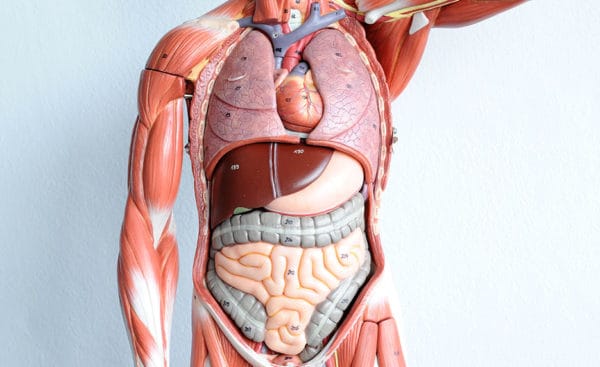

The scientific field is called bioprinting and just like 3D printers in other domains, the technology has grown in leaps and bounds over the past 15 years. 3D bioprinting is currently in use to create tissues for medical research and drug testing, with the broader aim of using the tech in regeneration: printing skin and, some day, organ tissues for transplantation.

Rather than relying on living or deceased donors, 3D bioprinting —literally, being able to print human organs on demand— would be a medical game-changer.

Rather than relying on living or deceased donors, 3D bioprinting —literally, being able to print human organs on demand— would be a medical game-changer.

But the task of growing complex and biologically functional tissues in the lab isn’t easy. Tissues are made of different kinds of cells arranged in specific patterns for the purposes of communication and functioning, and thus, reproducing that complexity, row by row and layer by layer is a difficult task. So far, only a few examples of viable printed constructs composed of more than one cell type exist.

Now, in a study published in the journal Nature Scientific Reports, researchers describe their new process, which involves droplet-based printer. Liquid droplets of mammalian cells (human embryonic kidney cells and sheep stem cells) are coated in a lipid oil shell and precisely placed via glass pipette into a three-dimensional structure on a minute scale.

“By this means, we have generated patterned constructs from two populations of cells,” say the study’s authors, “with high-resolution 3D features including layers and channels under 200 μm in width, within robust cubic-millimetre- scale structures.”

“We were aiming to fabricate three-dimensional living tissues that could display the basic behaviours and physiology found in natural organisms,”

The process proved effective, in that the printed cells turned out to have a high level of viability (90 per cent on average) and the human kidney cells were found to reproduce under culture conditions.

“We were aiming to fabricate three-dimensional living tissues that could display the basic behaviours and physiology found in natural organisms,” said Alexander Graham, study lead author from the Department of Chemistry at Oxford University in a press release. “To date, there are limited examples of printed tissues, which have the complex cellular architecture of native tissues.”

The researchers see the new technique as contributing to the wider impact of 3D printing on the field of medicine. “There are many potential applications for bioprinting and we believe it will be possible to create personalized treatments by using cells sourced from patients to mimic or enhance natural tissue function,” said Sam Olof, Chief Technology Officer at Oxford’s Synthetic Biology Centre.

Bioprinting is projected to become a multi-billion- dollar industry. San Diego’s Organovo, a publicly traded company, has developed its NovoGen MMX Bioprinter process and, like othercompanies, is developing tissue printing technologies with the “holy grail” goal of developing an organ printing method.

This year, Vancouver-based Aspect Biosystems signed a research deal with pharmaceutical company Johnson & Johnson to develop a 3D bioprinting process for creating meniscus tissues.

Leave a Reply

You must be logged in to post a comment.

Share

Share Tweet

Tweet Share

Share

Comment