Oakville, Ontario carbon science company Saint Jean Carbon Inc. (TSXV:SJL) has produced two samples of single layer graphene, produced without any chemicals or any mechanical systems that would harm the high order of carbon structure and wettability.

Oakville, Ontario carbon science company Saint Jean Carbon Inc. (TSXV:SJL) has produced two samples of single layer graphene, produced without any chemicals or any mechanical systems that would harm the high order of carbon structure and wettability.

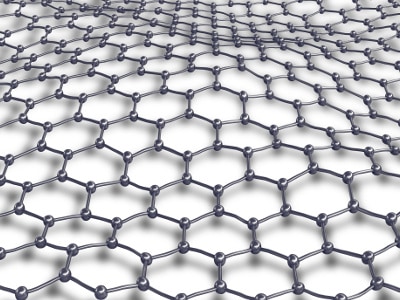

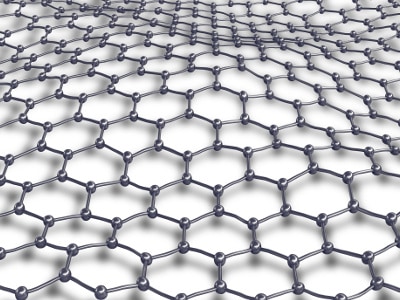

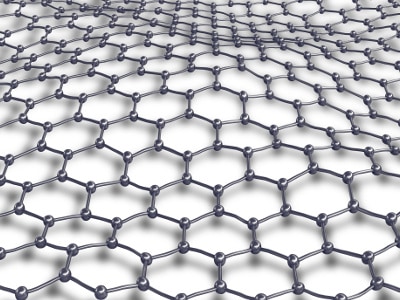

Graphene is a thin layer of pure carbon, bonded together in a hexagonal honeycomb lattice, composed of a single, tightly packed layer of carbon.

“We are very pleased to have both the material of such high quality and the know how to produce one atom thick graphene with zero impurities and be the most conductive and strongest material in the world,” said CEO Paul Ogilvie. “This milestone takes us another step forward as we continue to develop faster and more efficient systems to produce the material. More and more research into graphene in lithium-ion batteries continues to make real progress around the world, the better we understand the needs, the better prepared we will be in the future.”

The graphene samples have been sent to National Research Council of Canada (NRC), and will be used to help set the national standard for graphene production and quality.

In July, Saint Jean Carbon was invited by the NRC to participate as part of a special interest group that will develop and propose standards for graphene made by exfoliation methods from natural graphite.

For the consultation opportunity with the NRC, the project will be broken into a number of phases, with the first phase set to take approximately one year to complete.

The NRC’s aim is to work with graphene producers to develop standardized methods and to determine the optimal techniques to properly characterize graphene.

In the United States, the Graphene Council, along with a variety of other stakeholders, is working with the American National Standards Institute (ANSI) / International Organization for Standardization (ISO) Technical Committee (TC) 229 Nanotechnologies and the International Electrotechnical Commission (IEC) TC 113 Standards Development Groups, and is in discussion with the European Union Graphene Flagship on developing formal technical standards for graphene materials.

Saint Jean Carbon has been researching technology applications for graphite in lithium-ion batteries since 2007, and now has significant interests in graphite mining claims in Quebec, as well as lithium interests at the Whabouchi mine, located in the James Bay region.

In May, Saint Jean Carbon began construction on what will be North America’s first full mill and finishing line for the production of spherical, carbon coated graphite, a type of graphite that is sought after for lithium ion batteries, for the automotive industry among other verticals that require battery technology.

The mill design is modular, so that it can be set up at any battery manufacturing plant, and was developed in collaboration with two universities.

Saint Jean Carbon has filed a number of patents related to the mill, which was designed to produce an average output of 5,000 tonnes per year with less than 5% waste.

Graphene is the thinnest compound known to man at one atom thick, as well as being the lightest material known, with one square meter coming in at around 0.77 milligrams.

It is also the strongest compound discovered, between 100-300 times stronger than steel and with a tensile stiffness of 150,000,000 psi, is the best conductor of heat at room temperature, and also the best conductor of electricity known.

Graphene has potential applications as a super-material across a wide range of industries, including biological engineering, optical electronics, ultrafiltration, composite materials, photovoltaic cells and energy storage.

In 2013, a study released by the Universities of Bath and Exeter outlined graphene’s potential for revolutionizing the standard optic switches used in semiconductors for computing, potentially accelerating internet speeds by 100 times.

Saint Jean Carbon plans on producing more graphene from the samples gathered during their recent summer fieldwork, and is still waiting on the lab results of their summer work project.

Leave a Reply

You must be logged in to post a comment.

Share

Share Tweet

Tweet Share

Share

Comment